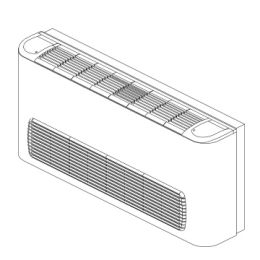

VCE X0

Centrifugal fan coil unit Frontal cabinet version Vertical installation Bottom air intake

Uncompromising style and performance.

Compact, slim fan coil units. Available in 12 different sizes. A wide range of options and accessories is available.

Structure:

in Z200 hot-dip galvanized steel sheet with a thickness of 0.8 mm and 1 mm (sizes 100 ÷ 120) insulated with closed cell polyolefin-based insulation. Condensate drain pan in hot-dip galvanized Z140 pre-painted 0.8 mm thick with closed cell polyolefin-based insulation 3 mm thick complete with connection for condensate drain external Ø 20 mm

Decorative cabinet:

in hot-dip galvanized steel sheet and pre-coated with a polyvinyl chloride film to guarantee high resistance to corrosion, pure white RAL 9010. The grilles for air diffusion and the flaps are instead made of injection-molded ABS, light gray RAL 7035 color.

Other colors or special finishes available on request.

Filter:

of standard supplied regenerable filter with galvanized steel frame and polypropylene filter fabric with efficiency class G1 * / EU1 **.

Alternatively, a wide range of filters with greater efficiencies are available, including G2 * / EU2 ** and G3 * / EU3 **. (* according to EN779 / ** according to Eurovent)

Fan section:

consisting of double intake centrifugal fans, with impellers in aluminum, or ABS statically and dynamically balanced, directly fitted onto the motor shaft. Single-phase asynchronous electric motor with overload protection, 6 rotation speeds (3 of which are connected).

The motor is directly coupled to the fans, and cushioned with elastic supports for the benefit of low noise. The series can also be equipped with innovative Brushless ECM motors, high head motors or motors with fail contact.

Coils:

in copper tube with aluminum fins with continuous pack blocked on the tubes by mechanical expansion. Brass manifolds equipped with Ø 1/2 ”and 3/4” female gas connections and easily accessible air vent valves. Hydraulic connections positioned on the left (front view), on request supplied on the right. The coils are reversible, so the connection side can also be reversed on site. The heat exchange coil is not suitable for use in corrosive atmospheres.

Customization:

our engineering is able to satisfy any customization requirement, ranging from simple aesthetic finishes to the satisfaction of specific dimensional, performance or application constraints.

Centrifugal fan coil unit Frontal cabinet version Vertical installation Bottom air intake

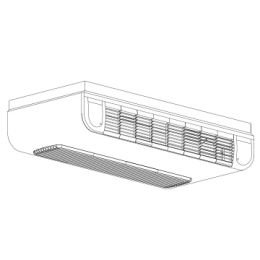

Centrifugal fan coil unit Frontal cabinet version Horizontal installation Rear air intake

Centrifugal fan coil unit Frontal cabinet version Vertical installation Frontal air intake with socle

Centrifugal fan coil unit Frontal cabinet version Horizontal installation Frontal air intake with socle

Centrifugal fan coil unit Frontal cabinet version Vertical installation Frontal air intake

Centrifugal fan coil unit Frontal cabinet version Horizontal installation Frontal air intake

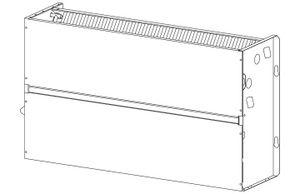

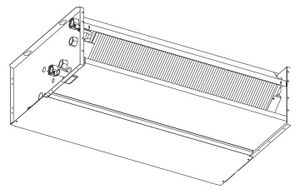

Centrifugal fan coil unit Concealed version Vertical installation Vertical air supply

Centrifugal fan coil unit Concealed version Vertical installation Vertical air supply

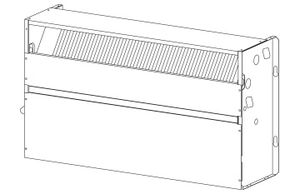

Centrifugal fan coil unit Concealed version Horizontal installation Horizontal air supply

Residential

Commercial

Hospital

Museum